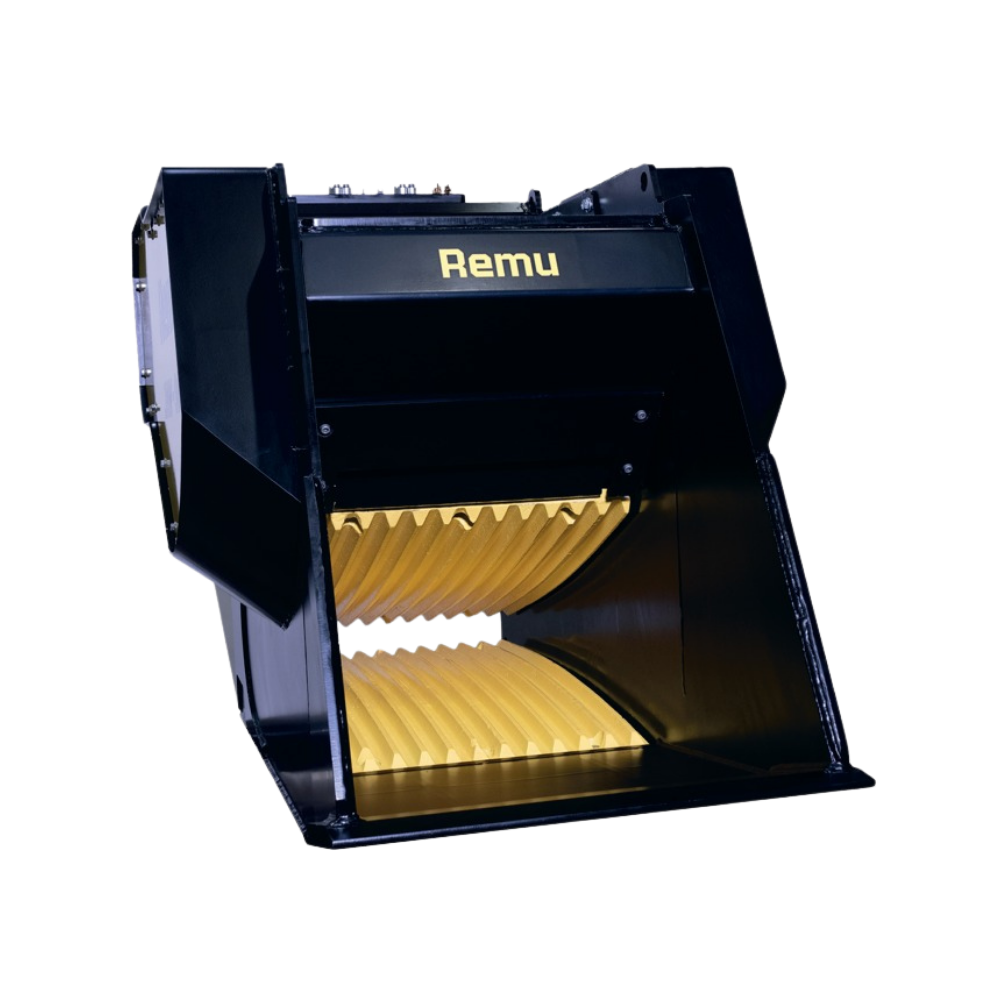

REMU Jaw 110

25 tonnes

4100kg

1450mm

1.0m3

Industry-Leading Warranty

1 year/1,000-hour warranty

Benefit from our confidence in product quality with a 1 year/1,000-hour warranty on all Remu buckets.

Features & Benefits

Quattro Movement

A unique crushing mechanism that starts crushing at the top, pushes material downward for high throughput, and provides a final cube-shaped output with minimal fines. Results in significantly higher productivity, longer jaw life, and a uniform, high-quality end product.

Reverse Function

Quickly clears blockages with the press of a button—no beating on the bucket required. Keeps the crushing operation continuous and efficient.

Highly Durable & Service Life

Built with a robust design, including jaw plates and wear parts that are easily replaceable. Equipped with central greasing as standard to minimise downtime. Known for delivering industry-leading longevity.

Low Operating Costs

A crusher bucket can operate with just one excavator, making it highly economical for on-site crushing. Ideal for smaller businesses seeking high ROI. This saves on transportation, landfill, and material purchase costs.

Versatile, Onsite Crushing

Handles a broad range of materials, including natural rock, concrete, asphalt, brick, tile, glass, and inert demolition debris. Fully portable—crushes on-site, reducing hauling needs and enabling immediate reuse of material.

Crushing Buckets Frequently Asked Questions

Where to use the crushing bucket?

Save time and money by processing demolition waste onsite. In an ideal case crushed material can be reused onsite, but even if the material needs to be transported to a recycling facility, crushing reduces the volume and helps to save transportation costs. A crushing bucket is also an affordable investment to recycling centres to process their material piles and turn those into valuable products.

Why choose the crushing bucket over a crushing plant?

Compared to a crushing plant, the bucket crusher is a more affordable investment and can solve a number of material handling needs. Also, the operating cost is only a fraction of that of bigger plants. You only need one excavator, one bucket and one operator.

What is the production capacity of the bucket?

The rotary crusher bucket offers a steady throughput, and with a number of materials a capacity of 60m3/hour can be achieved.

What happens if there is fine material mixed into material to be crushed?

Excessive fine material does not interfere with the crushing process in this rotary crushing bucket. This type of crushing technique is particularly suitable for processing mixed materials.

What wear parts does the CR 1100 have?

Wear parts for the CR 1100 consist mainly of carbide crushing picks which are quick and easy to change. Compared to the wear parts of some other type of crusher buckets the picks are much more affordable and convenient to store, transport or take to site.

What happens if something unbreakable goes into the bucket?

If a material is too hard to process, the rotor simply stops, after which the rotor can be reversed and the unbreakable material dumped out of the bucket.

What happens to steel wire/cables?

According to our experience most of the wire/cables go through the bucket.

Can it crush natural stone?

There are different types of natural stone, and some are easy to crush while others are not. Sandstone, shale, claystone, and soapstone are processable. The hardest natural stones, like granite, cannot be processed with our bucket.