REMU BUCKETS

AUTHORISED NEW SOUTH WALES DISTRIBUTOR DELIVERING SOLUTIONS FOR LOCAL CONDITIONS

Turn Your Excavator Into A Complete Processing Plant

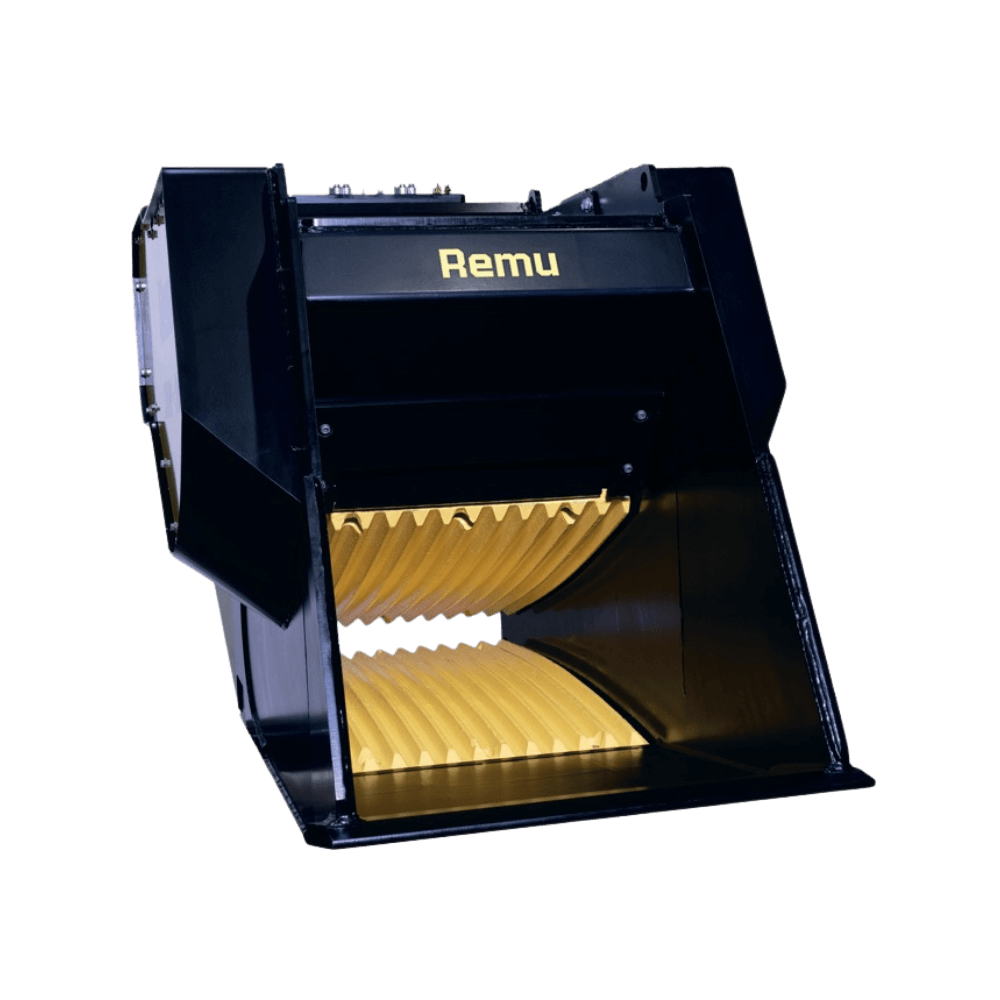

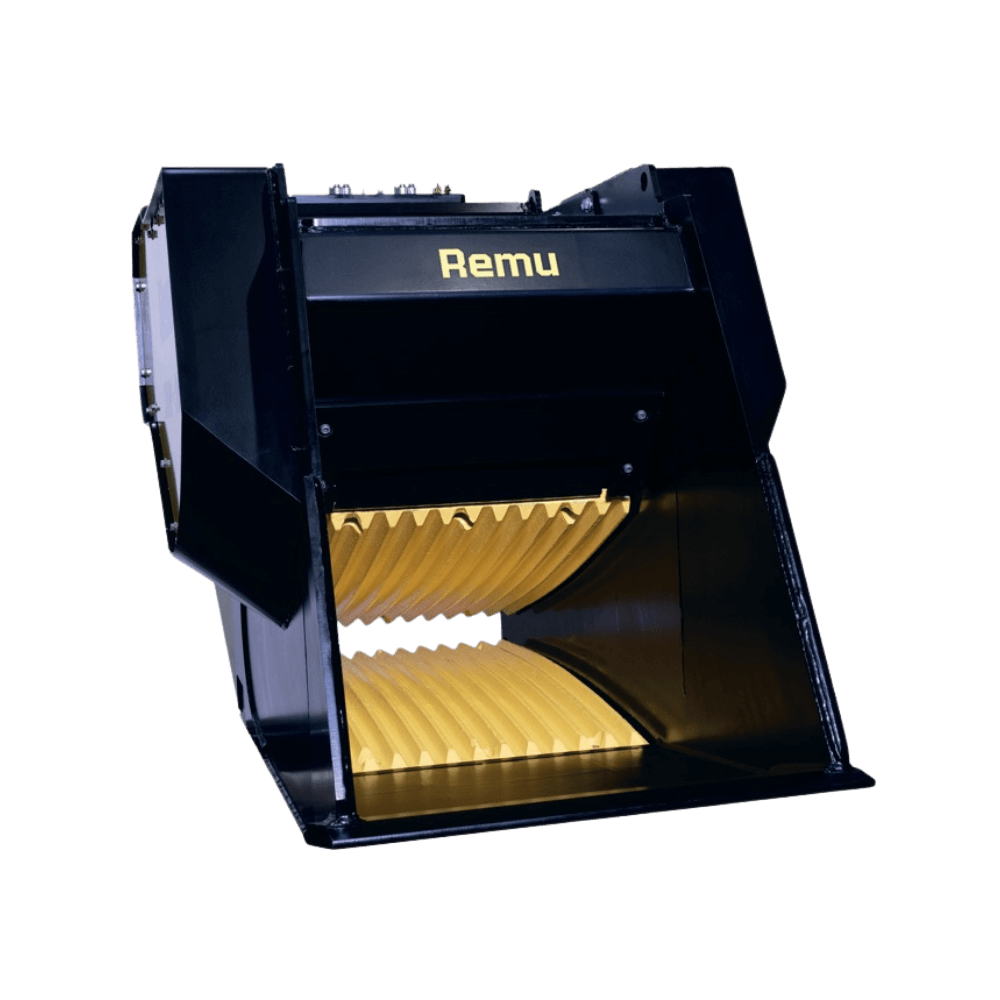

CR1100

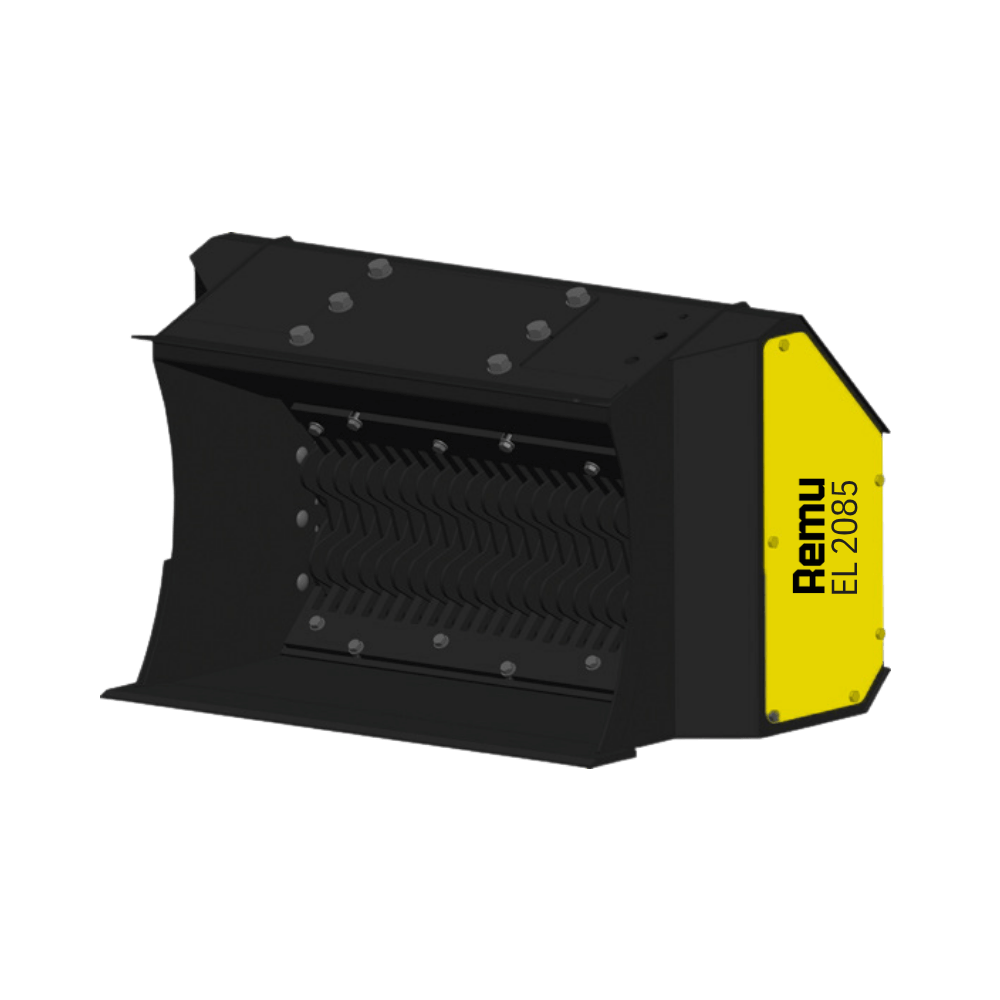

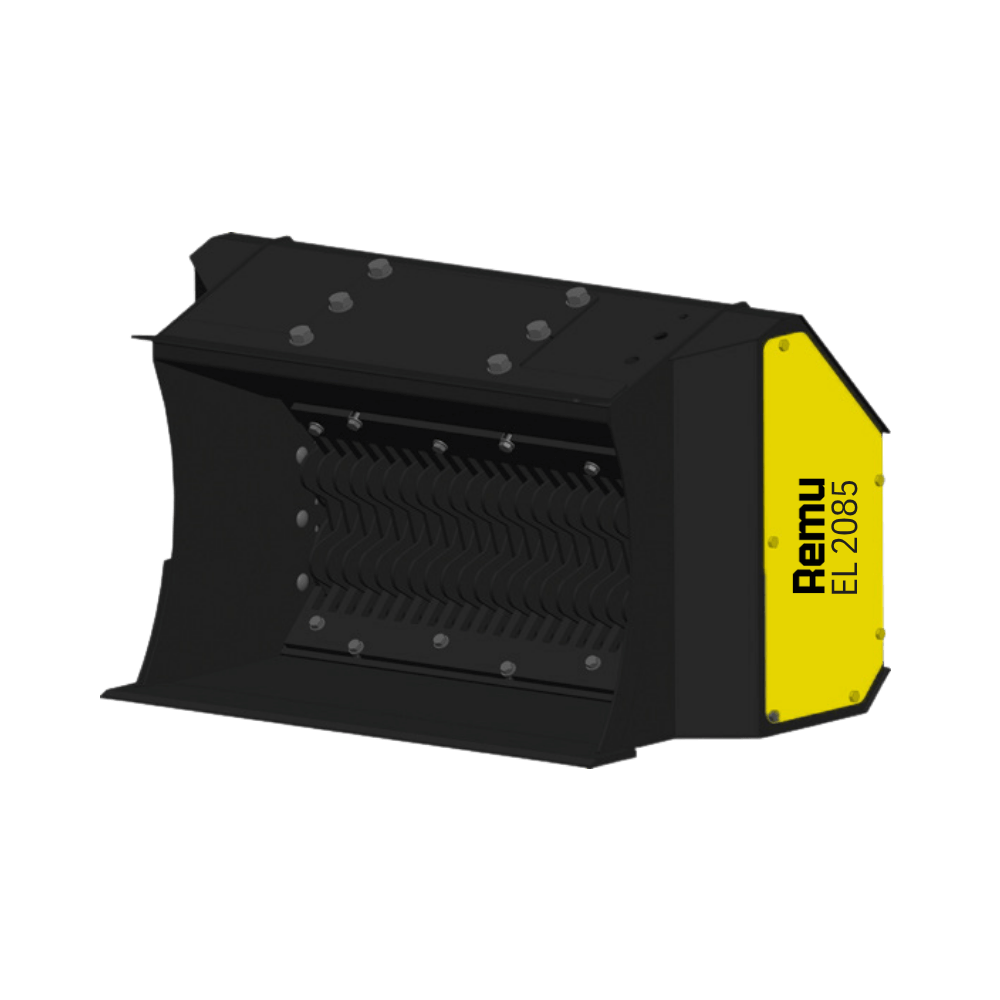

EL 2085

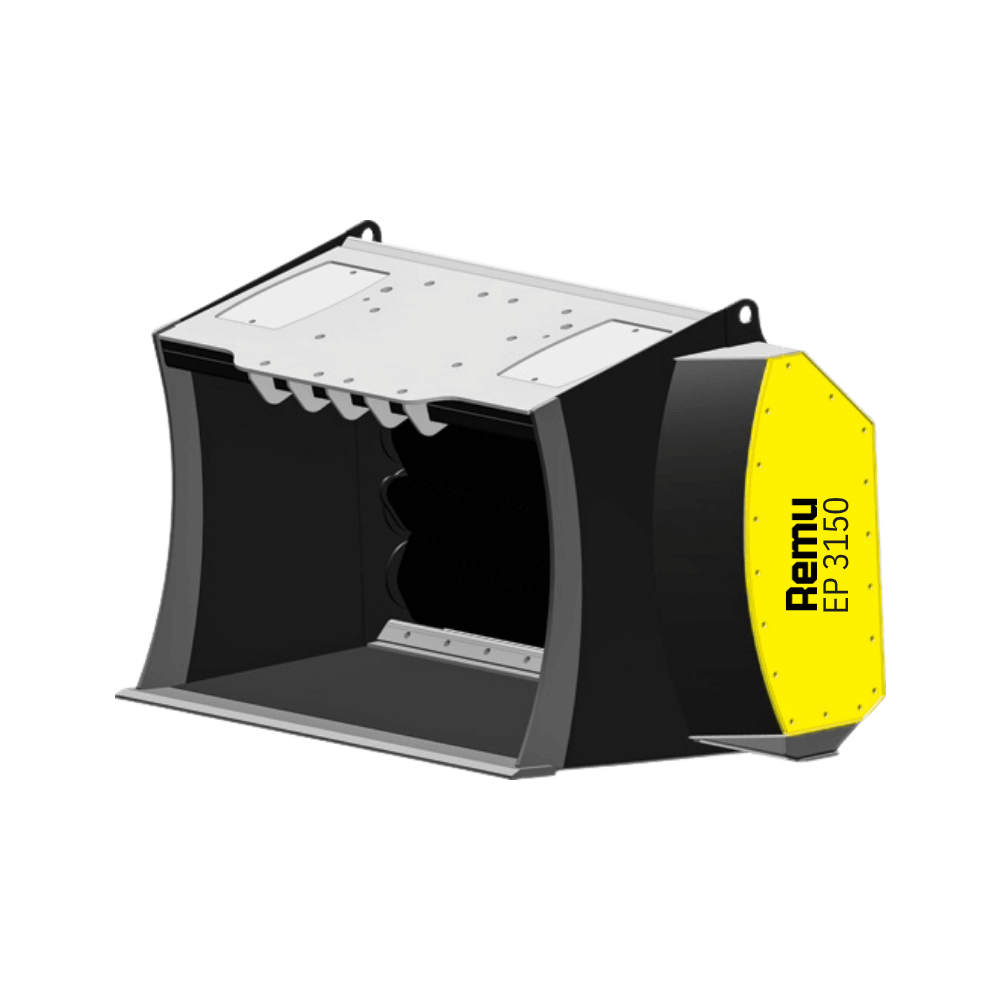

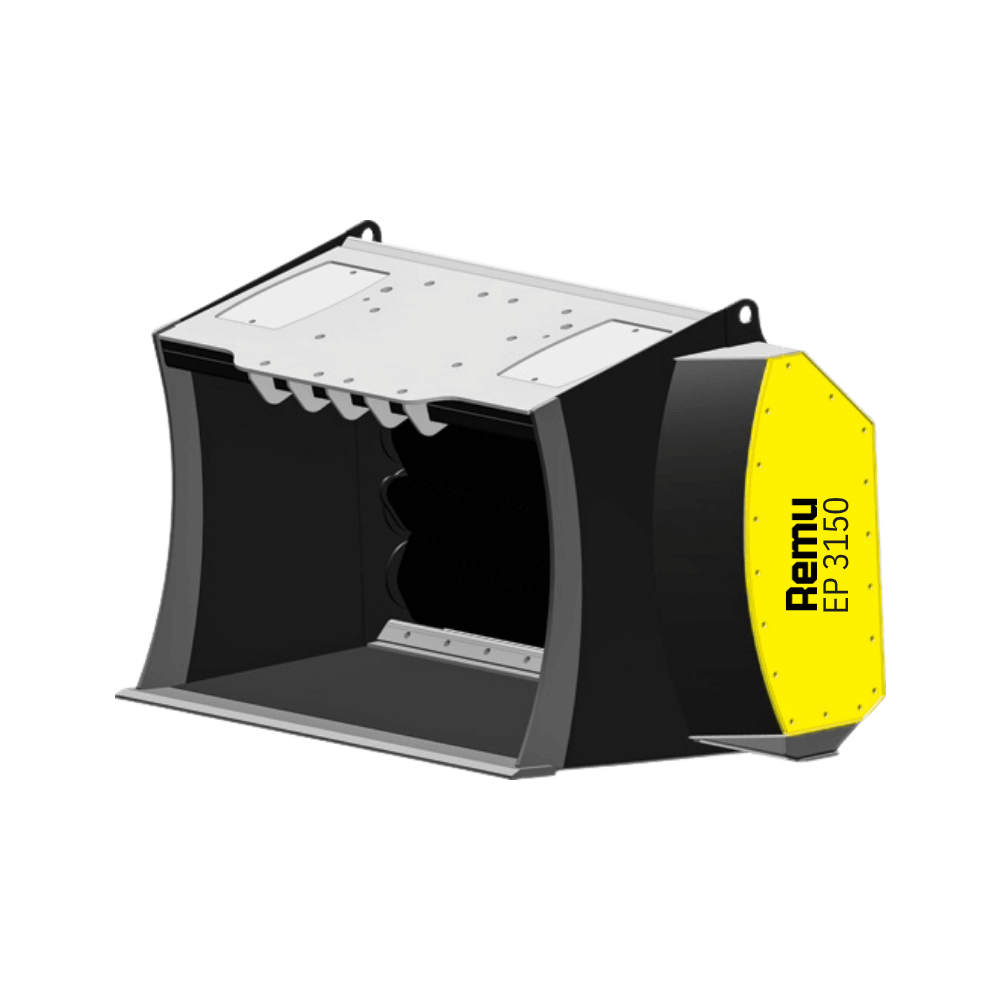

EP 3150

EP 4150

EE 3160

EE 4160

EE 3220

EE 4220

EE 4290

EX 140

PD 2160

PD 3160

XO 2090

XO 2150

Jaw 70

Jaw 110

Jaw 90

As your dedicated REMU partner, ONIS Equipment Group provides comprehensive access to their industry-leading range of screening and crushing buckets.

REMU’s focus on innovative attachment technology perfectly aligns with our commitment to supporting Australian contractors with equipment that maximises efficiency and reduces operational costs on every job site.

Equipped with the latest screening and crushing technology, each REMU bucket delivers exceptional performance, ensuring superior productivity, site profitability, operator efficiency, and versatility. With state-of-the-art engineering, robust construction, and intuitive operation, it’s easy to see why each model is the obvious choice for on-site material processing in any type of project.

Our REMU Screening and Crushing Bucket Range

Choose the perfect screening or crushing solution for your specific application.

Compact Excavator

Medium Excavator

Mini Wheel Loaders

Telehandlers

Telescopic Craler Cranes

Electric Products

1-2T 300mm Dig Bucket

1-2T 300mm Dig Bucket

1-2T 450MM Dig Bucket

1-2T 450MM Dig Bucket

1-2T 900mm Mud Bucket

1-2T 900mm Mud Bucket

1-2T 900mm Sieve Bucket

1-2T 900mm Sieve Bucket

1-2T Ripper Tyne

1-2T Ripper Tyne

10000L AquaTrans™ Portable Water Cartage Tank

10000L AquaTrans™ Portable Water Cartage Tank

1000L AquaMove™ Portable Water Cartage Tank

1000L AquaMove™ Portable Water Cartage Tank

1000L BlueMission™ AdBlue Tank

1000L BlueMission™ AdBlue Tank

1000L DieselCaptain™ Portable Diesel Fuel Tank Pod-With 60L/min Fluid Pump

1000L DieselCaptain™ Portable Diesel Fuel Tank Pod-With 60L/min Fluid Pump

1000L DieselCaptain™ Portable Diesel Fuel Tank Pod-With 80L/min Pump

1000L DieselCaptain™ Portable Diesel Fuel Tank Pod-With 80L/min Pump

1000mm 65mm Round Outer Extension

1000mm 65mm Round Outer Extension

1000mm 75mm Square Outer Extension (6 series)

1000mm 75mm Square Outer Extension (6 series)

1000mm A6 Multi Facet Tungsten Auger

1000mm A6 Multi Facet Tungsten Auger

1000mm A8 Multi Facet Tungsten Auger

1000mm A8 Multi Facet Tungsten Auger

1000mm RC6 Multi Facet Tungsten Rock Comination Auger

1000mm RC6 Multi Facet Tungsten Rock Comination Auger

1000mm RC8 Multi Facet Tungsten Rock Comination Auger

1000mm RC8 Multi Facet Tungsten Rock Comination Auger

1000mm S5 Rock Auger

1000mm S5 Rock Auger

1000mm S5 Tungsten Auger

1000mm S5 Tungsten Auger

EL2085

EL2085

EP 3150

EP 3150

EP 4150

EP 4150

EE 3160

EE 3160

EE 4160

EE 4160

EE3220

EE3220

EE 4220

EE 4220

EE 4290

EE 4290

EX 140

EX 140

PD 2160

PD 2160

PD 3160

PD 3160

XO2090

XO2090

XO2150

XO2150

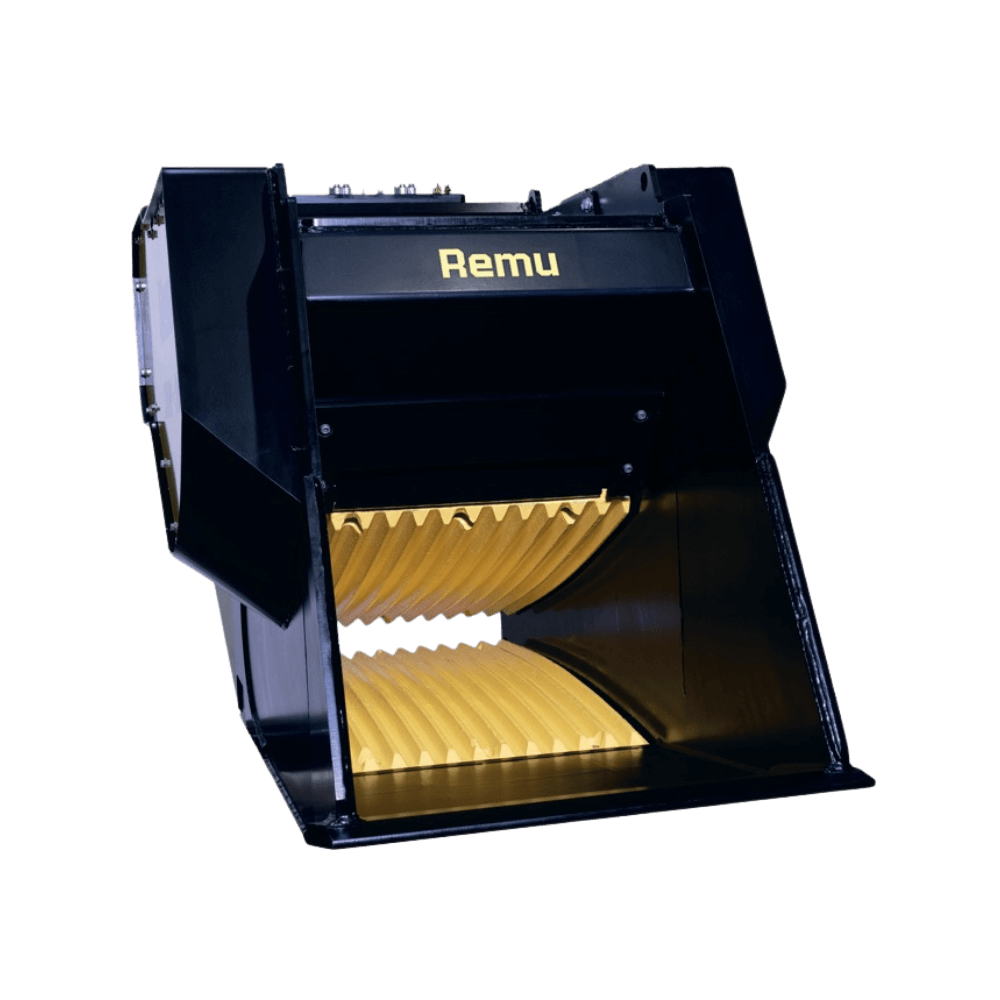

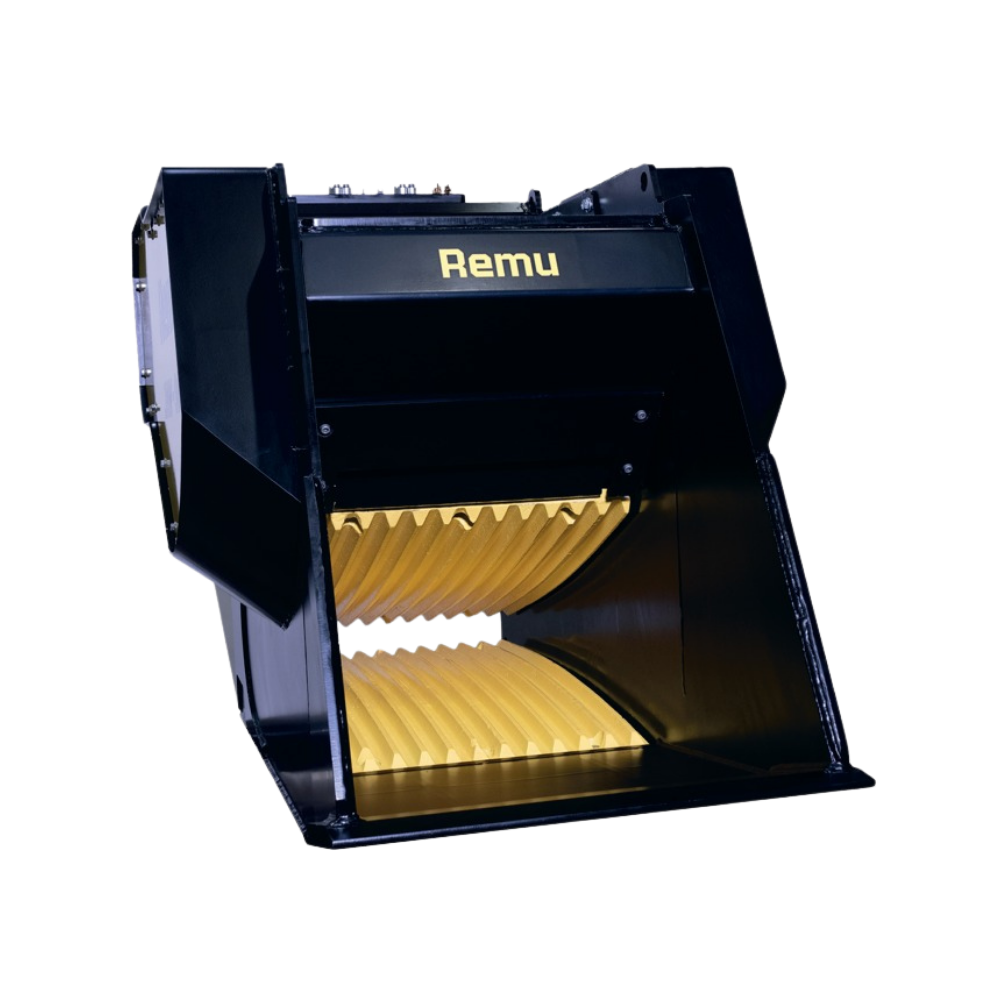

CR1100

CR1100

Jaw 70

Jaw 70

Jaw 90

Jaw 90

Jaw 110

Jaw 110

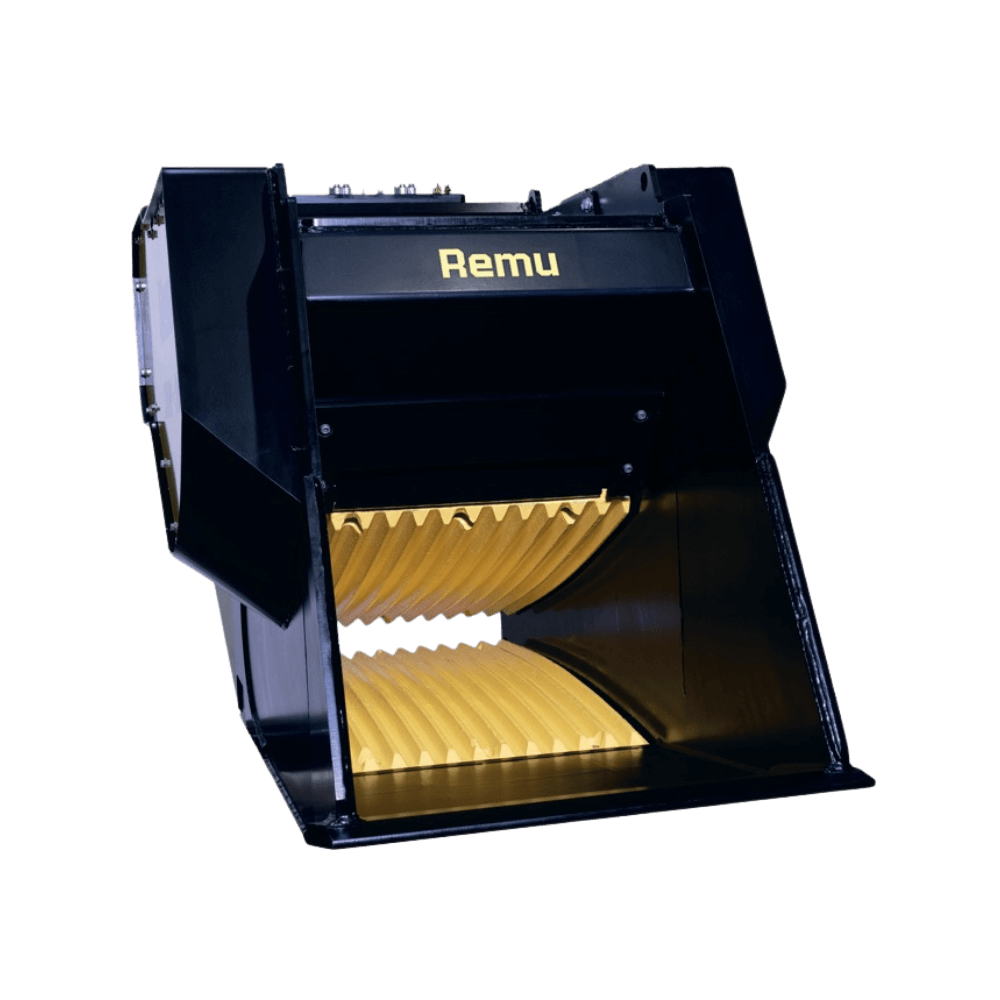

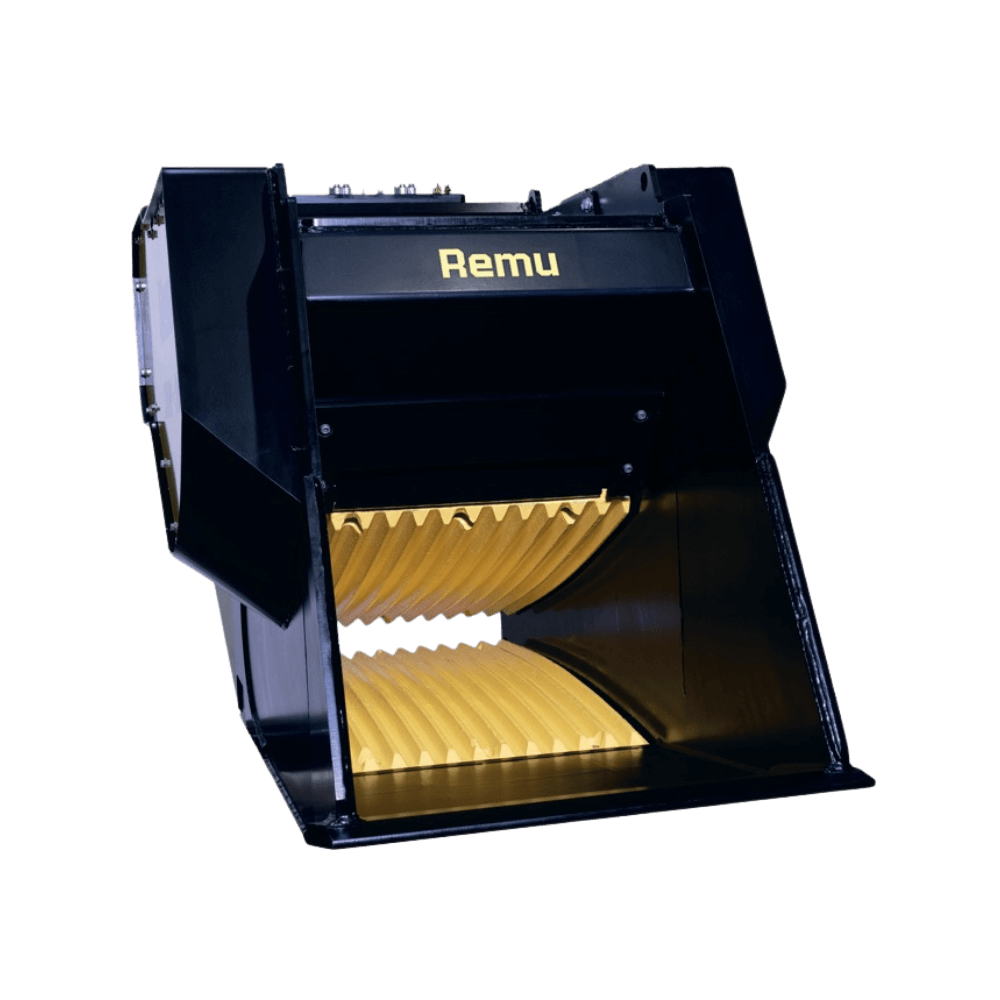

Features of REMU Screening and Crushing Buckets

Efficiency

Advanced safety features include obstacle detection systems and impact-resistant cab design, complemented by ROPS/FOPS certification for optimal operator protection in demanding construction environments.

Versatility

Exceptional maneuverability through high ground clearance and wide turning angles, allowing navigation of challenging terrain with switchable steering modes for confined space operation.

Durability

Available with straight or swivel skip options to handle diverse material transport needs, with hydrostatic transmission providing smooth acceleration and responsive braking for precise control.

Frequently Asked Questions

Find answers to common questions about REMU screening and crushing buckets

General - Remu Buckets

What excavator sizes are compatible with REMU buckets?

REMU buckets are available for excavators ranging from 1.5 tons to 70 tonnes. Our team will help you select the right model for your specific excavator and application requirements.

Can REMU buckets handle different types of materials?

Yes, REMU buckets are designed to process a wide variety of materials, including soil, gravel, sand, construction waste, demolition debris, and recycled materials. Different models are optimised for specific material types.

How much can I save by using REMU buckets on-site?

On-site processing with REMU buckets can reduce material transport costs by up to 80% and eliminate the need for separate screening equipment, providing significant cost savings and increased project efficiency.

What support do you provide after purchase?

ONIS Equipment Group provides comprehensive support, including installation assistance, operator training, maintenance guidance, and genuine parts supply to ensure maximum uptime and performance.

Are REMU buckets suitable for Australian conditions?

Absolutely. REMU buckets are engineered for durability and performance in demanding conditions. We stock models specifically designed for Australian applications and offer local support and service.

Screening Buckets

How much material can you load into the bucket?

REMU screening buckets can be loaded fully, which gives you more capacity at each scoop, whilst trommel style buckets can only be filled to 1/3 of the bucket volume.

What is the production per hour?

To process one bucket load takes approximately one minute. This includes the whole cycle of processing starting with loading, screening, and emptying out the oversized particles. Depending on the bucket size capacities can be in the range of 10 m³/h – 250 m³/h per hour

What is the operational cost of the screening bucket?

One operator, one machine and a screening bucket is an unbeatable combination when compared to what it takes to run a screening plant. By investing in a screening bucket, you save on investment cost, operating costs as well as fuel, maintenance and equipment transportation costs.

Some other buckets are cheaper than REMU buckets. Why is that?

A reliable and robust structure keeps your machine up and running saving you time and money in both operation and maintenance. Shafts are made of the highest quality steel which gives you the longest possible service life (much longer than other buckets with rubber stars or blades that are made from lower quality steels).

Why are there so many models of the REMU screening bucket?

A wide selection of models and our professional sales team help to guarantee that you will get the most suitable model and configuration of screening bucket and shafts for your machine, the material you process and the end result you require.

Can I use a bucket on asphalted surfaces?

The design of the buckets takes into consideration that clients may be working on asphalted surfaces and the bottoms of our buckets are reinforced with wear plates.

Is it difficult to operate the screening bucket?

It is very easy to learn how to operate a screening bucket. We supply a user manual with instructions for the correct use of the bucket and we will be happy to clear up any doubts you may have.

Why choose a screening bucket over a screening plant?

When comparing larger screening plants to smaller or average-sized screening buckets, some screening plants process more material per hour than screening buckets. However, a screening plant requires a wheel loader or excavator to feed it, which means you’ll be operating two machines and potentially needing a second operator. In many cases, the hourly production of the right model of screening bucket is the same as a screening plant, but the size of the initial investment and the operating costs are just a fraction of the size. With a screening bucket, productions of 250 m3 per hour are possible.

What maintenance does a screening bucket require?

Basic maintenance, or even changing the rotors, is easy to perform in any workshop. Daily maintenance consists of greasing the lubrication points for the bearings. Our aftersales service provides detailed instructions for all maintenance.

Crushing Buckets

Where to use the crushing bucket?

Save time and money by processing demolition waste onsite. In an ideal case crushed material can be reused onsite, but even if the material needs to be transported to a recycling facility, crushing reduces the volume and helps to save transportation costs. A crushing bucket is also an affordable investment to recycling centres to process their material piles and turn those into valuable products.

Why choose the crushing bucket over a crushing plant?

Compared to a crushing plant, the bucket crusher is a more affordable investment and can solve a number of material handling needs. Also, the operating cost is only a fraction of that of bigger plants. You only need one excavator, one bucket and one operator.

What is the production capacity of the bucket?

The rotary crusher bucket offers a steady throughput, and with a number of materials a capacity of 60m3/hour can be achieved.

What happens if there is fine material mixed into material to be crushed?

Excessive fine material does not interfere with the crushing process in this rotary crushing bucket. This type of crushing technique is particularly suitable for processing mixed materials.

What wear parts does the CR 1100 have?

Wear parts for the CR 1100 consist mainly of carbide crushing picks which are quick and easy to change. Compared to the wear parts of some other type of crusher buckets the picks are much more affordable and convenient to store, transport or take to site.

What happens if something unbreakable goes into the bucket?

If a material is too hard to process, the rotor simply stops, after which the rotor can be reversed and the unbreakable material dumped out of the bucket.

What happens to steel wire/cables?

According to our experience most of the wire/cables go through the bucket.

Can it crush natural stone?

There are different types of natural stone, and some are easy to crush while others are not. Sandstone, shale, claystone, and soapstone are processable. The hardest natural stones, like granite, cannot be processed with our bucket.